1350 aluminum alloy & properties-Mingtai Aluminum

Back

Back

2020-06-28 11:31

what is 1350 aluminum alloy ?

1350 aluminum alloy belongs to industrial pure aluminum with AI content not less than 99.5%. This series of aluminum alloys have good electrical and thermal conductivity, large latent heat of fusion, large light reflection coefficient, small thermal neutron absorption boundary and beautiful appearance, and other characteristics. Aluminum can form dense and firm oxidation in the air. The film prevents the intrusion of oxygen and has good corrosion resistance.

The heat treatment method of 1350 aluminum alloy can not achieve the strengthening effect, and only the cold deformation work hardening method can be used to increase the strength, so the strength is low. Suitable for the production of aluminum plates, strips, foils, tubes, rods (wires), mainly used in applications requiring high corrosion resistance and high formability, and parts with low strength requirements, such as chemical equipment, marine equipment, packaging materials, treatment Electrical materials, instrumentation materials and electrodes, etc.

1350 aluminum alloy properties

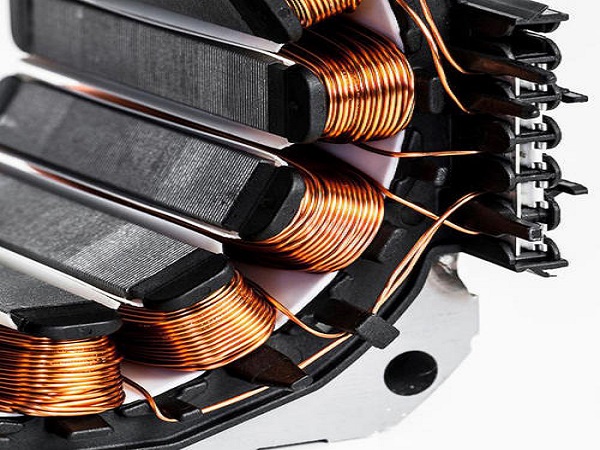

1350 aluminum alloy has a low density and high electrical conductivity and thermal conductivity, so it is often used as a transformer winding material. Secondly, 1350 aluminum alloy has good corrosion resistance and excellent insulation performance, good impact resistance, and good performance in the production of parts materials for electronic products.

Finally, 1350 aluminum alloy has good connectivity, and the surface can be sprayed or anodized during reprocessing. Aluminum alloy has good recyclability, so aluminum is a very environmentally friendly material. Mingtai 1350 aluminum alloy materials welcome users to receive free sample experience.