Trusted aluminum manufacturers near me | Mingtai Aluminum

Back

Back

2020-06-23 08:55

Aluminum plate is a very wide range of metal materials in modern industry, mainly used in aerospace, transportation, building decoration, packaging containers, machinery, electrical appliances, electronic communications, petrochemicals, energy, electricity, culture and health industries. The important basic material is the development of the national economy. Aluminum plate has many characteristics, Mingtai aluminum sheet manufacturers introduces to you.

1. Machinability

Aluminum plate has good cutting performance. However, after the production of various deformed aluminum alloys and alloys in various states, the processing characteristics are very different, which requires the use of special machine tools or technologies in the processing process.

2. Chemical milling

The removal of metals by chemical corrosion in alkaline or acidic solutions is a conventional and specialized thickening operation. This method can be used for the uniform removal of complex large surface area metals and has good economic benefits. This process is widely used to corrode prefabricated aerospace components to obtain maximum strength/mass ratio. The overall reinforcement of the aluminum wing and the fuselage is chemically ground to produce the best cross-section and the smallest skin thickness. Aluminum beams, longitudinal beams, floor beams and frames are also commonly prepared by this method.

3. Molding performance

This is one of the important characteristics of many aluminum plates. The specific tensile strength, yield strength, ductility and corresponding work hardening rate control the change of allowable deformation. The different states of the formability ratings of commercially deformed aluminum alloys depend on the forming process, and these ratings can only be used as a rough guide for the qualitative comparison of metal processing characteristics, that is, they cannot use the quantitative limit of formability value. The choice of state depends on the degree and nature of the forming operation. Suitable for deep drawing, rolling, small radius bending and other depths.

4. Extensibility

Aluminum plates can be forged into a variety of complex forgings, and a variety of final part forging design standards are available (based on the intended use). Deformed aluminum alloy forgings, especially those produced with closed dies, are usually more precise than the final shape of hot-forged carbon steel and/or alloy steel. For an aluminum plate of a given forging shape, the forging temperature varies greatly, which mainly depends on the chemical composition of the alloy being forged, the forging process used, forging strain rate, forging type, lubrication conditions, and forging and forging die temperatures.

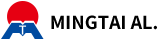

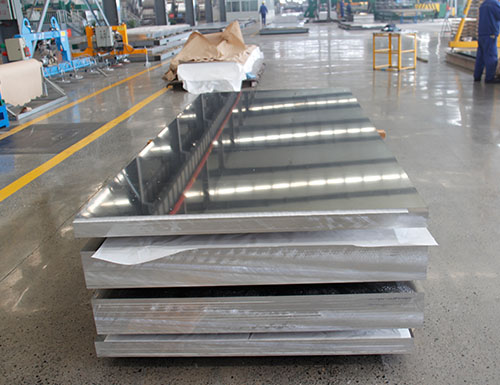

trusted aluminum manufacturers near me

Henan Mingtai Aluminum Co., Ltd. is headquartered in Gongyi City, Henan Province, China, which is rich in aluminum resources, has rich experience in foreign trade, and has established good cooperative relations with many foreign customers. It is a trusted aluminum manufacturers near me and can fully meet the processing needs of customers; Has standing stock products covering multiple grades and specifications of 1~8 series. High-quality aluminum alloy grades are: 1050, 1060, 1100, 3003, 3004, 5052, 5083, 5754, 6061, 6063, 6082, 8011, 8021, etc. The delivery time is short, and the products are widely used in machinery manufacturing, electrical appliances, electronics, automobiles, heat preservation, molds, aerospace, military industry, construction, printing and other industries.

Contact us ! Get factory price and free sample

email : sale02@mingtai-al.com