Henan Mingtai perfect after-sales service and advanced production equipment

Back

Back

2019-10-23 09:29

Henan Mingtai perfect after-sales service and advanced production equipment.

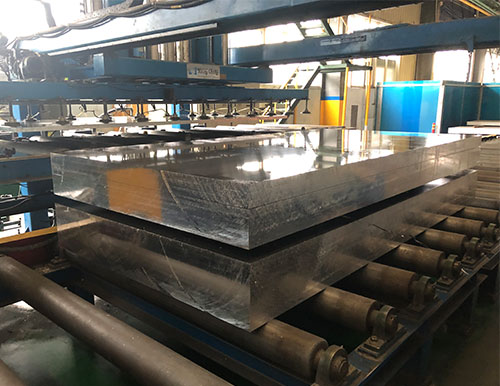

Advanced foil rolling: introduce international equipment,ameliorate the quality of aluminum foil and increase the rate of finished product.

Andritz plate roll is adopted, which provides a guarantee for the realization of good shape. The use of Honeywell thickness gauge ensures the accurate control of outlet thickness.

The use of Andritz plate roll improves the quality of the soft package foil of the Mingtai aluminum cell, making the surface of the product is more uniform and flat , the layout is smooth.The introduced Honeywell thickness gauge,surface tension, dyne pen test is not less than 32 Dane, and the dislocation layer difference of the aluminum foil roll is not more than ±1.0mm.

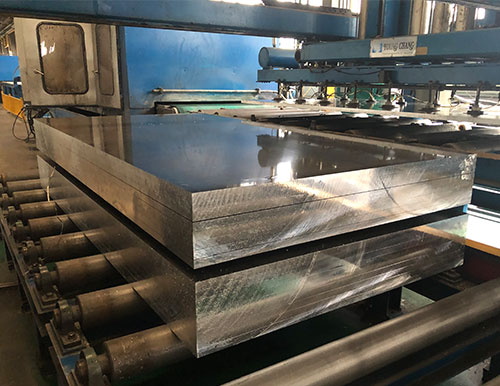

Furnace body equipment includes box furnace body,air circulation system, flow guiding device, blow wash and exhausting system, bayonet form heater, furnace door, furnace door lifting mechanism and pressing device, cooling water system and so on.The maximum working temperature of the furnace is 650 °C,the temperature difference is ≤ ± 5 ° C, and the metal annealing temperature is 120-580 ℃.At the end of the heat preservation,the metal temperature difference is ≤± 3 ℃. Greatly enhanced the product quality and the product workmanship level.

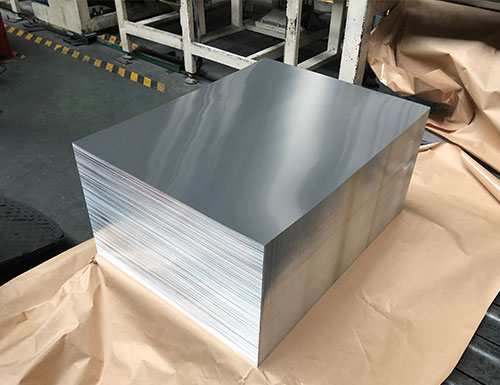

Mingtai as a leader of the domestic aluminum sheet/coil and foil roll ,provides customers with a comprehensive quality assurance system. From the aluminum ingot purchased from raw materials to the layer by layer inspection in the production process, to the quality inspection before leaving the factory, we provide customers with 360 degree worry free quality inspection packaging ,achieve one-stop worry-free procurement on a global scale.