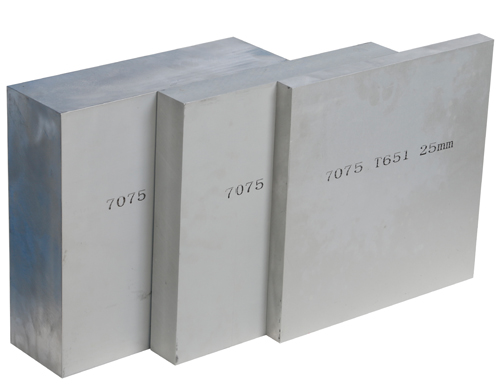

Is there any difference in the performance of aluminum alloy 5083H116 and H321, especially for seawater?

Back

Back

2019-03-08 16:49

H116: Aluminum alloy with a magnesium content of not less than 3.0%, after anti-corrosion treatment

H321: a state in which the aluminum alloy having a magnesium content of not less than 3.0% is subjected to stabilization after work hardening

Therefore, it is only necessary to find out the definitions of antiseptic treatment and hardening treatment.

H1*: Hot rolling, strong tension;

H2*: Continuous casting and rolling, strong tension, partial toughening

H3*: After internal stress treatment, stable performance

h4*: Painted or coated

H*2: 25% hardness treatment

H*4: 50% hardness treatment

H*6: 75% hardness treatment

H*8: >90% hardness treatment

H116: Applicable to products made of 5*** series alloy with magnesium content ≥4%. These products have specified mechanical properties and anti-flaking corrosion performance requirements.

In summary, H116 has good corrosion resistance, H321 has good corrosion resistance and stable performance. The mechanical properties of the two are similar, and they have good corrosion resistance after coating.

As far as I know, the construction of sea-going vessels is both possible. More mechanical properties need to be provided by the supplier. The relevant process can refer to the welding process and application research of the aluminum ship.