Henan Mingtai Aluminum Industry teaches you how to identify aluminum foil defects

Back

Back

2019-11-11 16:25

Aluminum foil has excellent performance and is widely used in the packaging industry, architectural decoration, automotive parts, electronic labels, electrolytic capacitors and other fields. Especially the use of packaging materials is very common, such as food, medicine, beverages, etc., which is well received by the market. Next, Mingtai Aluminum teaches everyone to identify the defects of aluminum foil, so as not to affect the later use.

1. Poor plate type

Due to uneven deformation, the surface of the foil is locally undulated, which is called poor plate type. According to the location of the defect, it is divided into intermediate waves, side waves, two-ribbed waves and composite waves. In the side part called side wave, in the middle called the intermediate wave, two parts are called composite wave, neither in the middle nor side called two-ribbed wave.

It is detected whether the degreasing is clean. Generally, after annealing, the degreasing grade is detected by brushing method. If the level specified by the brushing test is not reached, the aluminum foil may still have oil.

The phenomenon that the longitudinal edge of the surface of the aluminum foil is broken is called a split edge. In severe cases, obvious gaps are visible in the edges, which have a great impact on the later use.

A aluminum foil roll is not easy to open, and the multiple sheets are plate-shaped when opened. The free fall length of the product cannot meet the standard requirements. In severe cases, the single sheet cannot be opened, and the adhesion of the aluminum foil will seriously affect the production of the product.

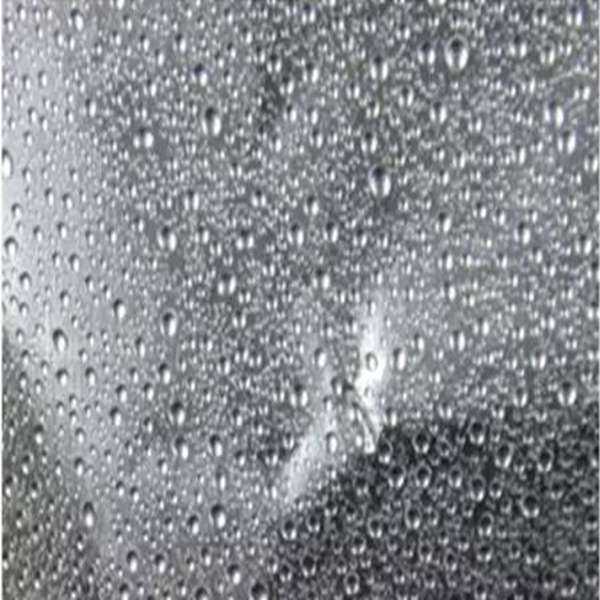

Pinholes are irregular holes that are visible on the surface of an aluminum foil. Aluminum foil is mostly used for packaging materials, and the pinhole problem affects the sealing property, so the requirements for the pinhole of the aluminum foil are very strict.

When the aluminum foil is double-rolled, the uneven spots on the dark surface of the aluminum foil appear as bright spots.

Mingtai Aluminum was established in 1997. It is a large-scale manufacturer of aluminum foil and sheet. It has factories in Zhengzhou, Gongyi and Xingyang, and has offices in Kunshan, Dongguan, Chongqing and South Korea. Mingtai can produce various specifications of aluminum foil from 0.012mm to 0.8mm thick. The quality is excellent, the price is fair, the delivery time is short, and the product exports nationwide. You can purchase it with confidence!

E-mail: sale02@mingtai-al.com

Whatsapp: +8615036049104

Wechat: 15036049104