Precautions For Bending Process Of Aluminum Plate

Back

Back

2019-10-15 16:46

Precautions For Bending Process Of Aluminum Plate

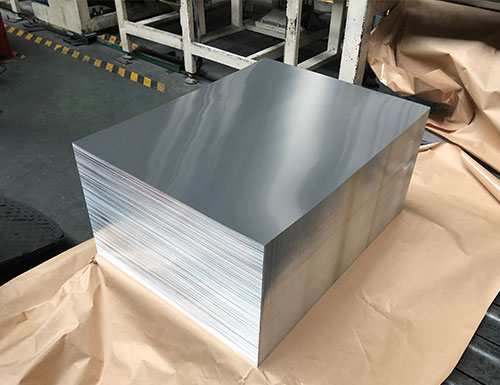

In daily life, we often see bright and unique aluminum plates, which are the effects after bending.

However, the aluminum plate is easily broken after being bent, and also easily breaks when it's anodized, so How can we avoid these situations?

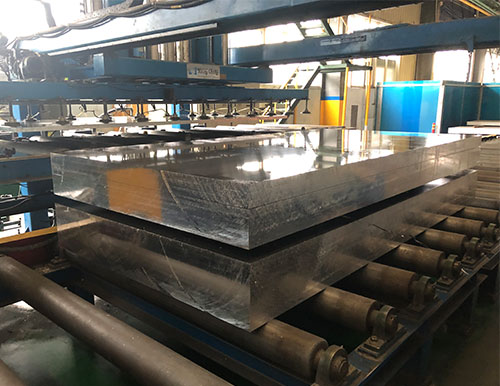

2, The thickness of the aluminum plate. Too thick aluminum plate is not easy to bend, we all understand, and it’s better to try to use a thin aluminum plate.

3, The size of the bend R angle. The greater the bend R angle is, the higher the success rate is, so try to increase the bend R angle.

4, The direction of the aluminum plate. The direction of the bend should be perpendicular to the direction of the aluminum plate, not parallel.

5,The aluminum plate parts that need to be drawn is preferable to bend and then pull the shape in the case where the process permits. Otherwise the probability of bending fracture will increase.

The above is the precautions about bending process of the aluminum plate. So that's it. Mainly to adjust these aspects, you can avoid the phenomenon of fracture after the aluminum plate bending.

China Aluminum Plate Manufacturer

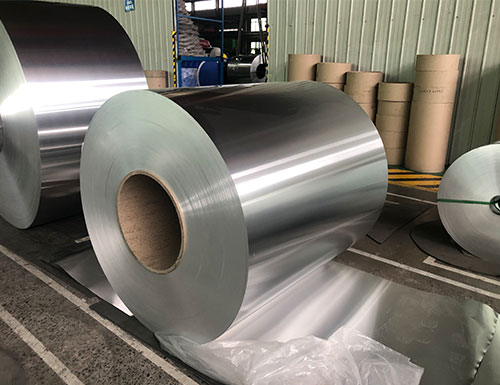

As the world’s largest aluminum plate producer, China’s aluminum plate production capacity accounts for more than half of the world’s total capacity. In order to alleviate the pressure of China’s aluminum plate overcapacity, many aluminum plate manufacturers will look to foreign markets, among which many China aluminum plate manufacturers have taken the lead in going abroad. Mingtai Aluminum is the most early. In 2012, Mingtai has sold its products to Southeast Asia, Europe and other regions. With the upgrading of Mingtai’s production technology and the improvement of product quality, the aluminum sheets produced have been widely exported to Europe, Southeast Asia, the Middle East, Africa, South America and other places, and have established a firm foothold in the local area.

E-mail: sale02@mingtai-al.com

Whatsapp: +8615036049104

Wechat: 15036049104