Aluminum used in life——6061 aluminum plate,it is everywhere

Back

Back

2019-09-20 17:20

Aluminum used in life——6061 aluminum plate,it is everywhere.

Nowadays,the field of food, clothing, housing and transportation in our life is inseparable from the application of aluminum alloys, from transportation vehicles to small mobile phones and clothes buckles. In the first century, ordinary steel plates have always been one of the commonly used raw materials in the transportation and manufacturing fields, but with the development of the modern transportation industry aims at high speed, heavy load and light weight, ordinary steel plates have gradually been replaced by aluminum plates and aluminum belts and aluminum foil.Many steel structure companies began to understand the market conditions and production status of aluminum plates.

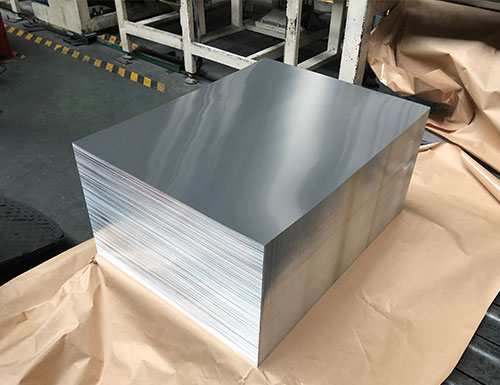

The 6061 aluminum plate is one of the most widely used aluminum plates products, and its production process and product quality need to be strictly controlled.

1. It shows excellent processing performance, good corrosion resistance, high toughness with no deformation after processing, easy coating, good oxidation effect, etc. It can maintain good operation after annealing. In particular, there is no stress corrosion cracking tendency, and it also shows excellent weldability and good cold workability.

2. Mingtai Aluminum “1+1 production line” greatly increased the output of 6061 alloy aluminum plate, which provided a solid foundation for the large-scale production of 6061 aluminum plate.

3. Mingtai Aluminum had obtained the "Weapons and Equipment Quality Management System Certification", "China Classification Society Factory Approval Certificate" and "SGS Automotive Aluminum Certification". At the same time, with the ISO14000 international certification, the production has been exported to foreign countries, which used in a variety of emerging industries.

4. Mingtai Aluminum invested heavily in the introduction of a world-class 3000T stretching machine, which can perform 1.0%--3.0% permanent tensile plastic deformation of the sheet in a specified time according to the process requirements. The transition to plastic deformation eliminates the residual internal stress of the product after quenching, ensuring that the product does not deform during processing.

In the process of cooperation with customer , Mingtai Aluminum summarized the specific requirements of customers for 6061 aluminum plates:

(1) The thickness tolerance of the board surface is required to be small (generally positive tolerance).

(2) The hardness should reach the standard (HB is above 95 degrees).

(3) The amount of deformation after processing is small.

(4) The flatness is better.

The 6061 aluminum plate production process is prepared from a semi-solid slurry to form a billet with a certain alloying element content, which is subjected to hot rolling cold rolling treatment,showing corner cutting and clear surface.So as to form a 6061 aluminum strip with a specific specification length and width. Through the strict quality control in the production process, the organization and mechanical properties of the 6061 aluminum plate castings have been developed to the greatest extent.For the later mold making, the required preheating temperature is 400-425 degrees, and the produced product is dense in structure and fine in grain, which is much better than the tensile properties and processing properties of ordinary steel sheets.

The 6061 aluminum plate material is popular at present, not only because of its high strength, corrosion resistance, but also related to current environmental protection. As a domestic high-quality 6061 aluminum plate manufacturer, Mingtai Aluminum is at the domestic advanced level in terms of production technology and technology, and strictly controls the quality of its products. The 1-8 series aluminum plate products produced by the company have won unanimous praise from the market and customers.