How to choose high quality and cost-effective aluminum panels

Back

Back

2019-09-16 14:19

We all want to buy the best aluminum panels with the quality is guaranteed, the after-sales guarantee, and the aluminum plate as a bulk, how to choose a better aluminum plate among many? Mingtai Aluminum's summary can be considered from the following five aspects.

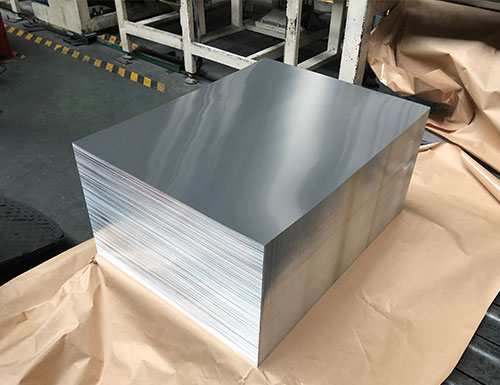

First, look at the outer packaging of the aluminum plate. Good packaging not only shows the strength of aluminum plate manufacturers, but also pays a large price for the product packaging, shows that manufacturers pay more attention to product protection. In addition, it also shows that the manufacturer's production management of aluminum sheets is in place.

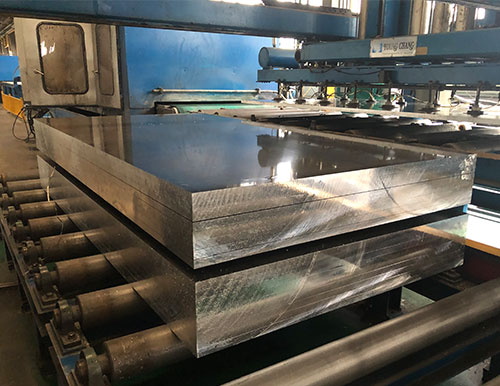

Second, look at the surface of the aluminum plate. Good aluminum plate, no defects such as roll marks, black spots, scratches, oil spots, corrosion, fission, etc.; flat plate shape, no obvious bending; single aluminum plate diagonally uniform; whole aluminum plate placed neatly, each aluminum plate The length and width are the same. If the surface of the aluminum plate is covered with a protective film, the protective film is uncovered, at least the entire width of the plate surface is viewed to avoid defects being covered.

Third, use a measuring tool such as a micrometer, meter ruler, vernier caliper to measure. According to the demand, the products provided by the aluminum plate manufacturers are selected for evaluation. According to the order of magnitude of the measured size, different measuring tools are selected to measure the thickness, width, length, unevenness, diagonal and other products of the aluminum plate. For specific dimensional deviation, refer to GB/T 3880. 1-2006. At least three points are selected for each measurement to measure whether the aluminum plate size or error is uniform and whether it is within the national standard.

Fourth, aluminum plate manufacturers are required to provide aluminum plate material qualification certificate. Good aluminum plate manufacturers will test the composition and performance of each batch of aluminum plates. After the aluminum plate manufacturer provides the material qualification certificate, check whether the composition and performance of the corresponding material of the material list are controlled within the national standard. For specific values, please refer to GB/T 3880-2006. Also pay attention to the material sheet which must be stamped with the manufacturer's official seal. If there is a problem during the use of the aluminum plate, the aluminum plate can be tested based on the material sheet and the quality objection is raised by the manufacturer.

Fifth, manufacturers after-sales service. Understand how the after-sales service of the manufacturer, if the aluminum plate manufacturers can solve the problem in time, there is no worries.