Cases

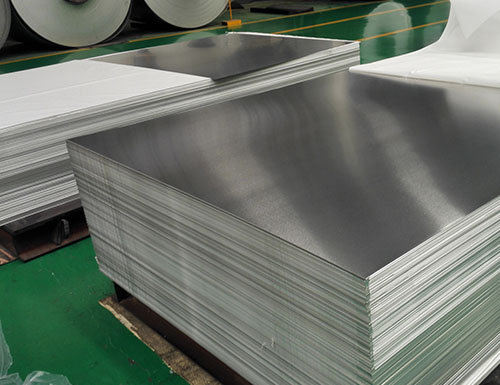

With high product quality and numerous technical patents, Mingtai aluminum alloy widely apply to different industry. Mingtai Aluminum's high level of calendering technology guarantees the flatness of the product.

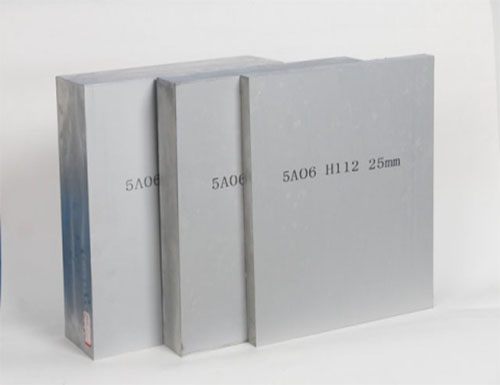

5A05 aluminum alloy introduction

Main features of 5A05 aluminum alloy

The strength of 5A05 aluminum alloy is equivalent to that of 5A03 aluminum plate, and it cannot be strengthened by heat treatment; the annealed state has high plasticity, and the plasticity is medium when half-cold hardened; the welding performance is good when hydrogen atom welding, spot welding, gas welding, and argon arc welding; high corrosion resistance, half-cold Machinability is good when hardened, and anodizing treatment is required when manufacturing rivets.

5A05 aluminum alloy application

5A05 alloy is usually used to manufacture welded pipes, welded fuel tanks and other liquid containers, and other parts that require high process plasticity, good corrosion resistance, and medium load; wire rods and rivets need to be anodized. In foreign countries, similar alloys (such as 5456) are used to make armor plates and high-strength structural parts. Storage tanks, pressure vessels, and marine products parts, etc.

5A05 alloy chemical composition

|

Silicon Si: |

Iron Fe: |

Copper Cu: |

Manganese Mn: |

Magnesium Mg: |

Zinc Zn: |

Aluminum Al: |

|

0.50 |

0.50 |

0.10 |

0.30-0.6 |

4.8-5.5 |

0.20 |

margin |

5A05 aluminum alloy mechanical properties

Tensile strength σb (MPa): ≥225

Conditional yield strength σ0.2 (MPa): ≥110

Elongation δ10 (%): ≥15

Note: Longitudinal mechanical properties of pipes at room temperature

Sample size: all wall thickness

Heat treatment specification:

1) Homogenization annealing: heating at 460~475℃; heat preservation for 12~14h; air cooling.

2) Rapid annealing: heating 310~350℃; holding time 30~120min; air or water cooling.

3) High temperature annealing: heating at 310~335℃; when the thickness of finished product is ≥6mm or <6mm, the holding time is 30~180min or 30~120min; air cooling.

4) Low temperature annealing: heating 250~300℃ or 150~180℃; holding time 1~2h or 2~3h air cooling

The 5A05 alloy has a higher magnesium content and good corrosion resistance. It has good weldability and is suitable for spot welding, atomic hydrogen welding, gas welding, and argon arc welding. Its machinability is poor in annealed state, and its semi-cold hardened state is still good.