Mingtai has a coup to solve the problem of uneven color of aluminum oxide film

Back

Back

2019-03-09 15:04

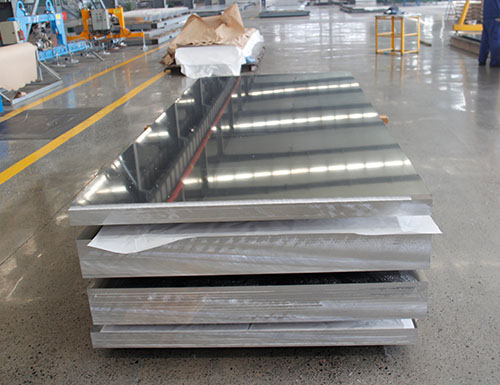

In the process of surface treatment of aluminum plates, some quality problems are often caused. For example, the surface of the aluminum plate often has some problems that are very troublesome for the user - the oxide film is uneven, the colors are inconsistent, and many colorful rainbows or even black spots appear. The existence of these problems not only affects the appearance of the aluminum plate, but also has some quality problems. It is imperative to solve the problem of uneven color of the oxide film of the aluminum plate!

As a large-scale enterprise with more than 20 years of experience in aluminum sheet processing and manufacturing, Mingtai Aluminum has a good understanding of the problems and solutions in the process of aluminum sheet processing. The following are the reasons why we have summarized the color unevenness of the aluminum oxide film and the corresponding Solution, I hope to help everyone.

First, the aluminum plate workpiece area is too large, the swing in the groove is too large during operation, and the contact, renewal and exchange of the edge and the center portion with the solution are too large, resulting in inconsistent color of the oxide film. Prevention method: When the aluminum plate is oxidized, the amplitude of the workpiece swing is small, and the static treatment is also possible. However, when the temperature of the solution is too low, the map-like spot is likely to appear, which is unnatural.

Second. When the aluminum sheet is processed, part of the aluminum layer is destroyed and cut off. The outer layer of aluminum is high-quality aluminum, and the inner layer of the package is miscellaneous aluminum. The difference between the two types of aluminum is large, so there is a “white hurricane” after oxidation. Like a spot. This phenomenon is often not understood by customers. It is recommended that manufacturers should explain more about the work and explain the original reason to avoid misunderstanding.

Third, the aluminum plate oxidation process operation problems, respectively, 1 workpiece alkali etching treatment is not complete, the local original oxide film, dirt failed to remove; 2 after alkali corrosion is not immediately light treatment, the surface of the workpiece is still alkaline; The workpiece is exposed to foreign matter during the transfer. When there is uneven color of the film layer, it is necessary to find the cause from various aspects and take targeted measures to solve it.

In fact, the oxidation of aluminum sheets is much more difficult than the oxidation of aluminum profiles. It is very difficult to obtain an aluminum sheet with uniform surface color and uniform oxide film thickness. In recent years, with the increase in the amount of aluminum used, higher requirements have been placed on the quality of aluminum sheets. It is believed that after continuous and in-depth research, the quality of the aluminum sheets produced is getting higher and higher!